LG Display has reportedly come up with a way to reduce the number of display driver integrated circuits used in its OLED TVs panels by half, and plans to do so in 2026. The move will enable it to reduce the manufacturing cost of its OLED panels, and perhaps even pass some of those reduced costs onto consumers.

According to a report in The Elec, LG Display has implemented a technique known as “Double Rate Drive” or DRD, which is used to double the signal transfer rate to its OLED panels. It enables more efficient communication between the driver and the display, reducing the number of integrated circuits required.

Because DRD enables twice as many signals to be sent, it only needs half as many drivers per panel.

LG Displays has reportedly begun collaborating with its main DDI supplier to enable this change. Display driver ICs consist of a source driver IC and a gate driver IC. The source IC sends red, green and blue signals to the OLED pixels, while the gate IC selects which pixels should receive the signal and generate light.

The DRD technique was first implemented in liquid crystal displays in the early 2000s, but it has proven to be challenging in the context of OLED displays, which require more precise control over the organic materials that make up its individual pixels.

LG Display’s existing 65-inch OLED panels currently use 16 DDIs, but from next year they will only require eight. There will be similar reductions for alternative OLED panel sizes, with the number of DDIs being halved. According to The Elec, this is a pretty significant breakthrough that will reduce LG Display’s manufacturing costs and perhaps even help to improve the performance of OLED displays.

By reducing the costs of its panels, LG Display would be better able to compete with rival Samsung Display’s QD-OLED panels. It’s not known if that company is considering DRD too.

However, The Elec notes that LG Display isn’t planning to implement DRD in its OLED monitor panels just yet. The challenge with monitor panels is that they have much greater pixel density and higher refresh rates than TV panels, and this means there are more demanding requirements in terms of drive speed and stability. As such, the implementation of DRD hasn’t yet become practical, and so OLED monitor panels will persist with the existing DDIC configuration.

LG Display’s strategic focus involves continuously optimising the profitability of its OLED display business, and this has become even more urgent now that the company has exited the LCD manufacturing industry. OLED TV panels are substantially more expensive than LCD variants, and so it’s essential for LG Display to optimise costs as much as it can, in order to maintain competitiveness with higher-end Mini-LED panels, which are based on LCD technology.

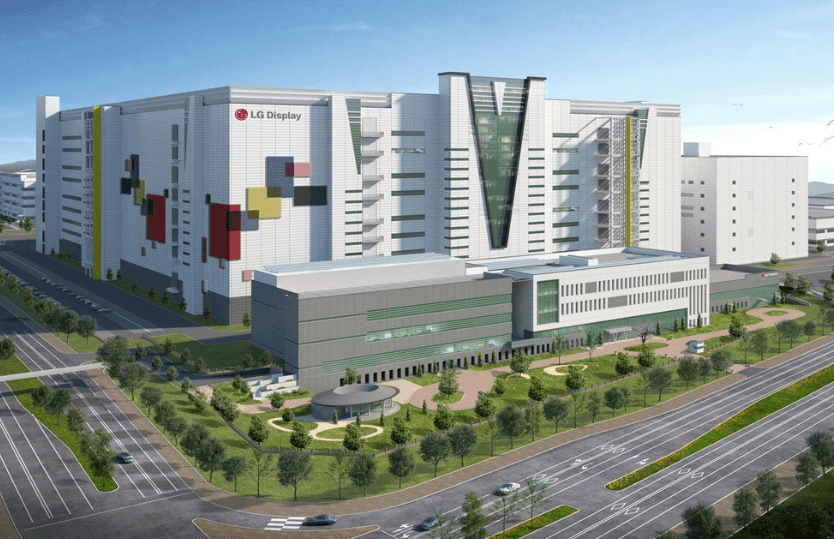

According to another Korean publication, iNews, LG Display is striving to implement improved cost structures at its OLED manufacturing hub in Guangzhou, China (pictured, above). That fab has a monthly production capacity of 90,000 Gen-8.5 OLED substrates (which are cut into various panel sizes), and around 65% of that capacity has already been depreciated, meaning it’s already churning out OLED panels at lower costs.

The company reportedly aims for the entire facility to be fully depreciated by the middle of next year, which will reduce its overall manufacturing costs further.

These cost optimisations explain why the bulk of LG Display’s large-sized OLED panels are manufactured in Guangzhou, rather than its other facility in Paju, South Korea, where manufacturing costs are higher.

In the meantime, LG Display is striving to improve the performance of its OLED displays, with plans to introduce a new blue phosphorescent PHOLED material that will dramatically increase the energy efficiency of its panels.