LG Display has said it’s ready to start comprehensive testing of a new manufacturing technique that will eliminate the need for fine metal masks in OLED production. Instead of using a mask to deposit the light-emitting organic materials accurately onto the substrate, the eLEAP technology uses more advanced lithography processes.

The eLEAP technique was first developed by Japan Display and unveiled to the world in 2022. It stands for “Environment positive, Lithography with maskless deposition, Extreme long life, low power, and high luminance, Any shape Patterning”, and it’s said to be an entirely new and more efficient way of depositing the materials for the pixels in OLED displays.

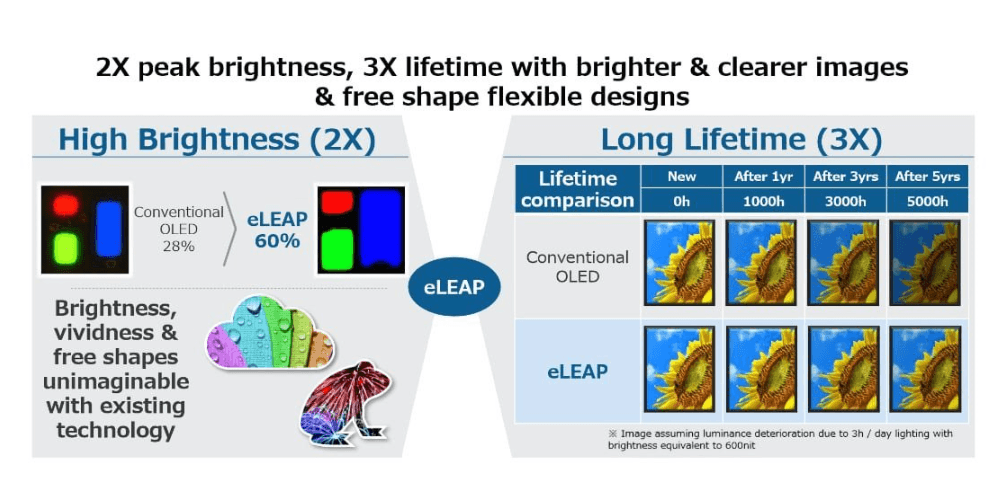

At the time it was announced, Japan Display made some impressive claims about eLEAP, saying it can double the peak brightness and efficiency of OLED materials, while extending their lifespan by around three-times.

This is because eLEAP enables a larger aperture ratio. Because the process is more efficient, it enables more of the space taken up by each OLED pixel to generate light. Because there’s more light, the display is therefore brighter. According to Japan Display, eLEAP expands the aperture ratio to around 60%, up from 28% with FMM-based OLED panels.

The eLEAP process could theoretically enable much brighter OLED displays than anything seen so far, exceeding even the latest generations – such as LG Display’s RGB Tandem OLED, which can hit a peak brightness of 1,500 nits. Potentially, it could help OLED panels to approach the incredible brightness of today’s most advanced Mini-LED displays, which can hit 3,000 nits and beyond.

Another benefit of eLEAP is an improved colour range, Japan Display has said previously. In its existing FMM displays, LG Display is forced to use a white pixel to help generate more brightness, but this would no longer be necessary with eLEAP, meaning that the light from the combined red, green and blue OLED pixels will be much “purer”. eLEAP is also said to use less power, reducing heat and reducing the threat of “burn-in” to expand the life of OLED televisions.

A report in The Elec says that after years of studying the tech, LG Display has decided to proceed with testing eLEAP at the E4 production line at its OLED display factory in Paju, South Korea. The facility is mostly used for manufacturing larger OLED panels for TVs, and it already has the necessary chemical vapor deposition machines required for eLEAP.

LG Display decided it could afford to do this because the E4 facility is not currently operating at full capacity. Instead, the bulk of its large OLED panel manufacturing takes place at its newer facility in Guangzhou, China, where production costs are lower.

LG Display will need to invest in some “additional research equipment” for the project, but it’s not clear what kind of outlay it will make here. The Elec stressed that this is merely a test run for eLEAP, and it’s not going to commit to any large-scale investment soon.

The aim of the test is to verify that the company can actually utilize eLEAP with its OLED technology, and then assess how effective the displays are in various applications, such as TVs, automotive, monitors and mobile applications.

It should be noted that LG Display isn’t the only display maker experimenting with eLEAP. Last November, it was reported that Samsung Display had acquired a vertical deposition machine from Applied Materials to research eLEAP’s capabilities itself. In addition, the Chinese display maker Vixionox is working on a variation of eLEAP known as “ViP”, with plans to apply the technique to its Gen 8 OLED facility, which is currently under construction.