Samsung Display’s QD-OLED displays might soon get a performance and reliability boost after the company announced it’s working with Japan-based TSK Corp. on the development of a new kind of material for blue OLED pixels.

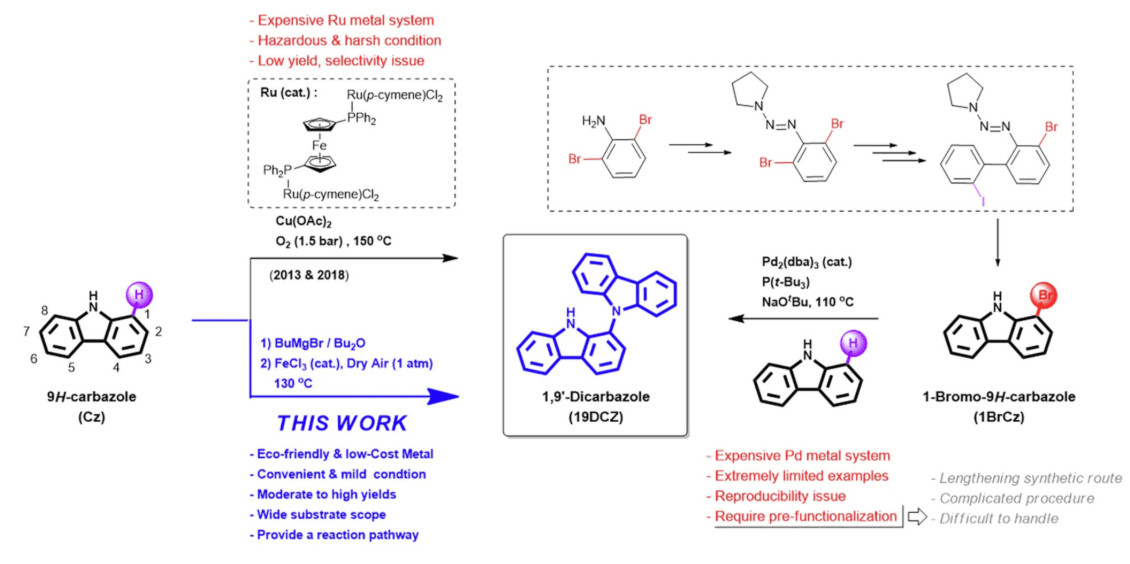

The companies said they initially plan to collaborate on the development of host and electron-blocking blue OLED materials, based on TSK’s novel iron catalyst technology.

According to TSK, today’s OLED displays typically use palladium catalysts to create their blue pixels. But palladium is an extremely rare metal that can only be sourced at the required scales from Russia and South Africa, presenting procurement challenges for display makers. Palladium is also fairly expensive, and the process of extracting it from the ground is very polluting, the company said.

To reduce the industry’s reliance on palladium, TSK has created a new, more environmentally-friendly chemical process that uses iron as a catalyst. Iron is a much more abundant and cheaper resource that can be found all over the world.

Beyond the fact that iron is lower cost, more sustainable and easier to source, TSK’s process is said to simplify the “reaction steps” involved in creating blue OLED materials. It also supports the construction of molecular structures that have traditionally been extremely difficult to synthesise using palladium. As a result, TSK says it has been able to create a novel compound that shows lots of promise as a key structural ingredient for OLED materials. In early tests, it says its performance has exceeded existing palladium-based materials.

That explains how it has gotten the attention of Samsung Display, and the companies are now working together to try and achieve the efficiency and durability required for OLED products. While it’s fairly simple to create energy-efficient green and red OLED pixels, the blue ones have always struggled to match that performance, and the materials used are less stable and have a much shorter lifetime. As such, the announcement is an encouraging step that could result in longer lifespans for OLED panels while simplifying what has long been seen as a technically challenging manufacturing process.

TSK and Samsung Display have published a joint research paper that explores the concept, which they now hope to commercialise.

The companies are not alone in trying to improve the structure of blue OLED materials. Earlier this year, researchers from the University of Cambridge and University of Manchester published a paper showcasing a new technique for creating more energy-efficient and lower cost blue OLED materials, utilising a new "oxadiazine" host material that also holds significant promise.